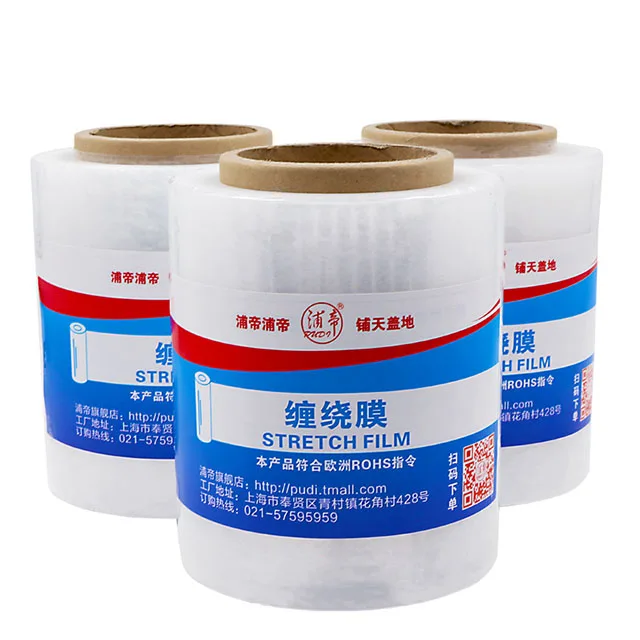

Shanghai Pudi Packaging specializes in stretch film, silage film and bopp tape, providing innovative and reliable packaging products for various industries.

Contact Info

-

Email

[email protected] -

Phone

+86-15021050640 -

Address

Factory No.7, No.568 Yangyue Road, Nanqiao Town, Fengxian District, Shanghai